Metlab Heat Treat has a long history of success, providing heat treating services to a wide range of industries. To ensure continued success and to elevate Metlab’s quality and efficiencies, the company recently hired Chris DiMascio as the Vice President of Operations.

“My goal is to strengthen the core business from an operations perspective,” remarks DiMascio. “Processes need to be solidified, and new ones need to be put in place. This includes having the right people working on the right things. To accomplish this, we will be implementing Lean principles throughout the organization. The first year will be the equivalent to “polishing the apple.” As an example, we are already beginning to establish ownership and accountability throughout the organization.”

Mark Podob, Metlab’s President and Owner comments, “His work with us over the past few months has resulted in many major improvements to our operation. We are looking forward to the great experience that he brings to Metlab as we seek to grow our heat-treating operations.”

Mr. DiMascio has over thirty years of broad experience (including plastics, metals, and chemicals) in engineering and operations. He was most recently principal of OpX partners, his consulting firm, and prior to that COO of the Process Technologies Division for Johnson Matthey Inc., a British company with nine facilities worldwide.

He holds a Bachelor of Science Degree in Mechanical Engineering and an MBA in Business Management from Penn State University.

We are continuing to monitor the development of the situation around COVID-19. Our goal is to remain to be the high quality and responsive supplier to our valued customer base. Metlab is following the rules and guidelines established by authorities to ensure the safety of our employees and the community.

While state-wide or local “non-essential” business closure orders are in effect in many areas, our facility remains open. Metlab is a contractor to the United States Government and qualifies as an “essential” business and is therefore exempt from the closure orders issued to date.

As a supplier to many “life-sustaining businesses” and companies, Metlab will continue to remain open to provide heat treating services and support to our customers.

We thank all our employees, suppliers, and customers for your support, flexibility, and patience. We look forward to continuing to serve you in the future.

Sincerely,

Mark Podob

President

Ninety-two years: that’s how long Metlab — the heat treatment company based in metropolitan Philadelphia — has been in business. Metlab began operations in 1928 as a manufacturer of struts for WWII-era aircraft. Today they specialize in heat treatment of parts and serve over 7,000 clients, who trust Metlab to treat parts ranging from under 1 pound in weight to over 25 tons.

Metlab runs on great equipment and great people. Their 125,000 square foot facility is home to 30 furnaces, the largest of which is 15 feet in diameter and 12 feet tall — among the largest of its kind in North America. Forty-one employees keep the facility’s operations humming at a brisk pace, and on any given month, Metlab completes work for at least 1,000 clients.

That’s quite a journey given the company’s humble beginnings almost a century ago, and Metlab has been able to improve and grow their business by embracing innovation and smart energy use at every opportunity.

Consuming Responsibly

Perhaps not surprisingly, the powerful furnaces used by Metlab consume substantial amounts of energy, and energy is the company’s single largest expense. All but two of Metlab’s furnaces run on natural gas, and according to President Mark Podob, getting up to 1,850 degrees Fahrenheit — the required temperature for certain treatments — demands a lot of gas.

In fact, natural gas is so critical to Metlab that Podob remembers a cross-town competitor going out of business in the wake of the 2014 polar vortex, which caused gas prices to spike to $125 per dekatherm. Protecting your bottom line from price spikes is all the more critical when your business uses as much energy as Metlab does.

Metlab has trusted Direct Energy Business with all of their energy needs for nearly 10 years, and currently has its natural gas price locked in until 2023. While getting a low price is necessary, budget certainty is paramount to Metlab’s procurement strategy.

“What’s really important is that we know how much our natural gas will cost so we can properly do our pricing and have cost control,” Podob explains. “It is so much better being with Direct Energy Business for all our energy needs. The price we pay is terrific and the service is phenomenal. It’s been a great relationship.”

Additionally, Metlab makes a point of investing in technology to cut down on energy use. Installing recuperators — which recycle exhaust gas back into burner gas, increasing the proportion of gas that is ultimately combusted — on two furnaces cost the company $75,000 per furnace about ten years ago. With help from a Department of Energy grant, Metlab made the investment, forecasting a payback period of roughly three years. This proved an underestimation, as the recuperators actually paid for themselves in a mere six months, significantly reducing the facility’s natural gas consumption and creating long-term cost savings.

Multilayered Motivations

The attitude toward energy use at Metlab includes more than just bottom-line calculations. While there is a clear business case for implementing energy-efficient features, the company sees smart energy use as a key to making Metlab a better place to work.

A recent six-figure investment for efficient light fixtures and LED lighting is forecasted to pay for itself in two years, but Podob argues that another critical benefit is creating a brighter, better-lit workplace. Furthermore, given that many workers at the facility are well-versed in furnace technology and know how much energy it takes to run the equipment, Metlab’s energy-saving investments are a signal to them that the company thinks of itself as a place where people can feel proud to work.

Metlab employees take pride in challenging themselves as craftspeople. In addition to treating parts for military helicopters, naval vessels and aircraft carriers, Metlab operates a six-foot diameter, 16-foot deep furnace where they perform treatments on parts for oil wells and drilling rigs. But they work with small parts, too, and certain projects requiring highly precise treatments have tested the company’s expertise. Hobbyists hoping to restore vintage automobiles and aircraft have approached Metlab with springs and other components in need of careful heat treatment; the company has even applied black oxide treatment to a suit of armor. There’s no project too niche, too complex or too unwieldy for Podob and company. Metlab has the equipment and know-how to heat treat almost any part imaginable.

A New Generation

Metlab know-how extends to workforce development. The company trains and cultivates employees to become an integral part of the operation, including those without significant experience in the field.

Metlab also hosts educational facility tours and offers internships and full-time opportunities to future engineers. Podob believes hands-on learning helps students connect classroom studies with real-world engineering to discover what it takes to bring products and parts to life.

The company manufactures and heat treats car components, like gears and axles, at no charge for the Society of Automotive Engineering (SAE) students. SAE clubs all over the country look to Metlab for help designing and building their competition vehicles. The company has donated services and engineering consultation to students from Georgia Tech, Rowan University, Drexel, Temple, UPenn, and the U.S. Naval Academy.

Podob says, “We are always open to helping students learn and be a part of the manufacturing process for their projects. We like to do that; we like to give back.”

Beyond Energy

Metlab’s community-oriented philosophy extends to eco-responsibility and thoughtfully considering their entire operation. For example, Metlab previously used city water to cool their furnaces to the tune of about $12,000+ per month. Their new re-circulation system has cut water consumption and costs by more than two-thirds.

For Podob, it’s a matter of “getting the timing right” with respect to innovations and improvements. If ideas like water re-circulation, better lighting or recuperators for the furnaces will reduce Metlab’s environmental impact while also making financial sense, Podob considers it “a no-brainer.”

In addition to the long-term fiscal benefits, energy efficiency and smart procurement create value for the company’s culture. When a company does its part to protect the environment by using resources responsibly, the effect is accumulative; it becomes a better organization to do business with, a better place to work, and sets an example for others. It’s not easy to stay at the forefront of the industry after almost 100 years of business, but with the right attitude and openness to change, Metlab has set themselves up for a bright, productive future.

“I come to work every day and I look forward to being here,” Podob reflects. “Every day is a challenge and every day is different. We can do a job tomorrow and I may not see that again for five years, and then on Monday, a different project will come in that I haven’t seen for five years. As a job shop, we’re always working on something new and fresh.”

Article Source:

Direct Energy Business

https://business.directenergy.com/about-us/customer-stories/metlab?&vendorId=mktgc&utm_medium=social&utm_source=linkedin

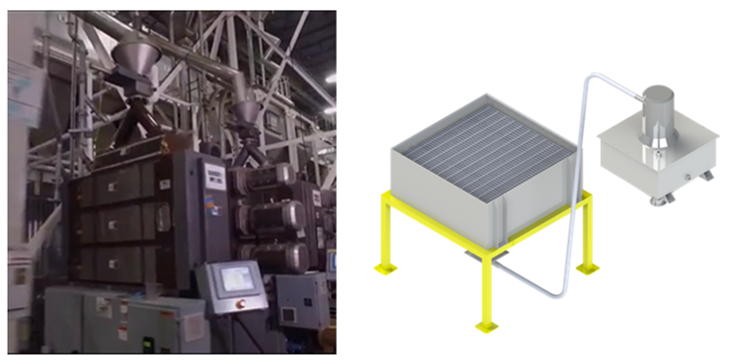

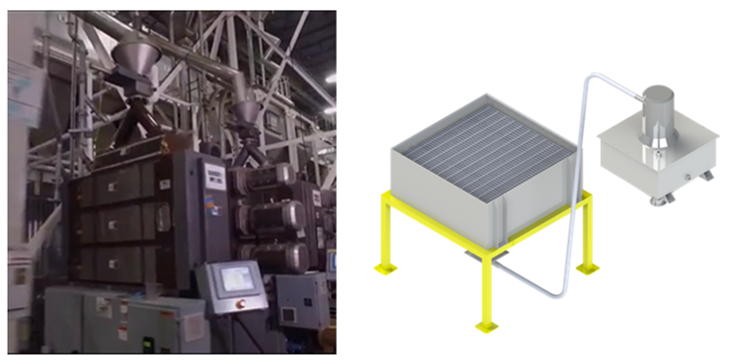

Metlab provides many heat-treating services for a wide variety of parts and industries. A reoccurring project for coffee grinding equipment features nitrocarburizing of the piping and elbows that comprise the transportation system for the coffee beans. In this system, the coffee beans are moved from the roaster to the grinder. Coffee beans are abrasive, and the customer engineered the required heat treatment to solve a wear problem.

Coffee grinding equipment and transportation system with piping and elbows.

The specification requires the process to nitrocarburize the piping and elbows to form a white layer. This white layer is also known as a compound zone, and contains mixed nitrocarbides, with a minimum of 0.0001″ on the I.D. of each bent elbow. The heat treated piping elbows must not be polished or sandblasted to maintain the specification. The typically angled piping and elbows are about 5 5/8″ in diameter x 6′ for each leg and are made with ASTM A53 Type E Steel, Grade A, or B Low Carbon Steel.

The parts comprise of the following:

• Part: 5″ schedule 10 elbows with a 60″ CLR.

• Size: 5.5625″ O.D. x 5.2945″ I.D. x various lengths and angles

• Weight: 25 to 40 pounds each

Nitrocarburizing is a case hardening process that diffuses nitrogen and carbon into ferrous metals at 1050°F. The process temperature is below the tempering temperature of most steels, and the advantage of this process over other case hardening techniques is that there is no distortion or significant size change to the component being processed – the only size change is about 0.0005″ per side, the growth being the result of the diffusion of the hardening elements into the surface of the components. Therefore parts may be finish machined before heat treating. The process is used to improve scuffing resistance, enhance fatigue properties, and provide corrosion resistance.

Metlab processes the piping and elbows in approximately 72 hours, utilizing one of the two large pit furnaces on site. In addition to coffee grinding parts and components, Metlab provides nitrocarburizing for gears, bearings, and other parts that can benefit from improved wear resistance.

Metlab has a long history of supporting academia to encourage and educate young engineering students. This past October, students from the Industrial and Systems Engineering program at Temple University accompanied by their professor, Dr. Julie Drzymalski, toured the Metlab heat treating facility. The purpose of the tour was to expose the freshman and sophomore students to manufacturing and also stress the importance of heat treating to the success of engineered metal products. Each Metlab department was featured along the tour route, including vacuum heat treating, metal quenching, induction flame hardening, carburizing, nitriding, black oxide treatment, and several other process areas. The students also visited the quality control department, which is complete with a metallurgical lab.

Industrial and Systems Engineering Program at Temple University

students getting ready to tour Metlab’s Heat Treating Facility.

The students were guided by Mark Podob, Metlab’s Company President. “Providing a “hands-on” opportunity for engineering students gives them an invaluable experience to learn what it takes to bring products and parts to life.” Podob remarks. “We are committed to supporting students and faculty to keep young minds engaged with manufacturing processes, equipment, and employees. In fact, Metlab hires students from Temple and other universities for both internships and full-time employment.” Dr. Drzymalski noted that Metlab uses 5S Lean Manufacturing in its operation, which was just covered one of her recent classes with the students, emphasizing classroom education with real-world engineering.

Other processes featured during the tour included Annealing, Heat Treat Stress Relieving, Straightening, Carbonitriding, and Cryogenic Treatment.

For questions about Temple University’s Engineering Programs, Dr. Drzymaksi may be contacted at Julie.drzymalski@temple.edu.

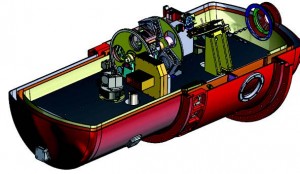

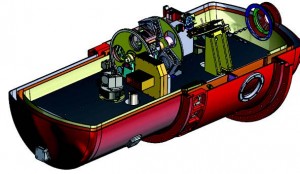

Metlab heat treats and processes many parts and components for the United States military, government projects, and NASA. Recently, several telescope and mirror parts made of pure aluminum, copper, and titanium were treated for the new High-Resolution Mid-Infrared Spectrometer (HIRMES), that NASA is developing to expand the boundaries of astronomy research.

Cutaway illustration of HIRMES instrument.

A heavily modified Boeing 747SP that carries a 2.5m-diameter infrared telescope flies above ~95% of the Earth’s atmospheric water vapor, allowing astronomers to gain access to wavelengths that are not possible to observe from the ground, even with the most powerful ground-based telescopes.

Modified Boeing 747SP equipped with an infrared HIRMES telescope

HIRMES’ prime investigation is a detailed study of the processes leading to the formation of planetary systems over a spectral range rich in ionic, atomic, and molecular lines. The HIRMES science program will determine the structure and evolution of protoplanetary disks and will increase our ability to model these systems as they evolve from homogeneous disks to fledgling planetary systems.

At the beginning of their lives, stars significantly interact with their environments, and the HIRMES program will advance our understanding of the ways these interactions regulate star formation.

Recently Industrial Heating Magazine featured Metlab as part of a company profile as a member of the Metal Treating Institute:

Metlab isn’t your typical commercial heat treater. Founded in 1928 as a manufacturer of aluminum spars for biplanes, the company is credited with the patent for the first drop-bottom gantry furnace.

But today, the Wyndmoor, Pa.-based company is known for its huge pit furnaces and its ability to heat treat parts weighing anywhere from a few ounces to 50,000 pounds. In fact, Metlab has more than 30 furnaces on-site – including pit furnaces as big as 15 feet x 12 feet deep, which are believed to be the largest in North America.

Load of modified H-11 steel rods, 2 feet in diameter x 16 feet long, being prepared for air quenching. The company also has vertical pit furnaces measuring 4 feet in outside diameter x 16 feet deep with the ability to extend to 18 feet deep for heat treating long, slender parts used in oil drilling, mill pinion shafts, bar stock and tubing. A pit nitriding furnace and a car-bottom tempering furnace (6 feet x 9 feet x 16 feet) complement the large-parts department, and the company has several integral-quench batch furnaces and support tempering equipment for heat treating small parts.

Metlab acquired the John V. Potero Company in 2001, allowing it to process small parts and provide a wide range of heat-treatment services. These include case hardening, nitriding, protective atmosphere annealing, hardening, quenching, tempering, stress relieving, solution annealing and age hardening. What’s more, the recent investment in vacuum furnaces has further expanded the company’s offerings into bright hardening of tool steels and stainless steel.

Deep-case carburizing and hardening, as well as nitriding of large and small gears and shafts, are core competencies of Metlab. The ability to heat treat these parts to precise and accurate case depths and hardness while maintaining geometric integrity makes the company unique in the field of commercial heat treatment. What really sets the company apart from its competition, however, is its ability to process parts in large, atmosphere-controlled equipment specifically designed for processing gears, pinion shafts, bearing races and other large industrial components.

Fabricated gear weighing 40,000 pounds being removed from Metlab’s largest pit furnace. This longtime MTI member offers more than thermal processes. With three full-time metallurgists on staff and an in-house metallurgical laboratory, Metlab has the ability to analyze microstructure and case depth to ensure all parts are processed accurately and on time. The company also offers black oxide finishing, failure analysis and metallurgical consulting.

As for recent developments, a recirculating water system funded in part by a grant from the Department of energy coupled with rebuilds of the two large pit furnaces has made Metlab more competitive from a cost-savings and water-recycling standpoint.

As for the future, Metlab intends on acquiring new equipment and adding new processes to complement its core offerings. Recent projects involving the heat treatment of nose cone and rocket exhaust gas nozzles as well as long, slender down-hole tooling indicate the need for more capacity to process large parts. In addition, capacity to nitride gears, axles, shafts, and large industrial valves calls for equipment upgrades.

Metlab is active in providing heat treat services and consultation to colleges and universities that feature automotive engineering. The Rowan University Society of Automotive Engineering (SAE) group reached out to Metlab for consultation on their latest project, a Baja endurance racing vehicle.

The SAE is a hands-on engineering club focused on challenging students to learn how to design, build, and race vehicles. The students were looking for a source to manufacture gears and pinions. Metlab provided a manufacturing source as well as heat treating consulting and the carburizing and hardening services at no cost.

“We discussed the heat treating process at length with the students so they could gain insight into the processes and expand their manufacturing and engineering experience.” comments Mark Podob, President of Metlab. “The heat-treating process is critical to the durability of these key components in racing, especially for off-road, where the conditions are extreme. We are always open to helping students learn and be a part of the manufacturing process for their projects.”

Example of a gear and pinion for off-road vehicles

Engineering in action! Student driver in the Canadian competition.

SAE BAJA collegiate challenge is all about durability and endurance. Students are tasked to build an off-road vehicle powered by a 10 HP Briggs & Stratton engine that can make it through a 4-hour endurance race. The car must perform through rocks, mud, sand and an assortment of challenging obstacles. The vehicle design was the first series Rowan participated in and marked the start of Rowan Motorsports in 2002.

The Rowan Society of Automotive Engineers with team cars.

“We would like to thank Metlab again for the sponsorship! With your help, we were able to finish our new car and compete with it in a competition in Canada. The blue car is our brand-new car. The red and tan cars are from previous years. Our next competition is in April in Tennessee.”

Elizabeth Henning

President of Rowan SAE

Metlab has assisted students at Georgia Tech, Temple, Drexel, University of Pennsylvania, and the U.S. Naval Academy on their SAE Automotive Engineered Car programs, providing them with no-charge heat treatment services and engineering consultation. In partnership with several gear manufacturers who utilize Metlab for their heat treating requirements, the students have been able to procure gear sets for their vehicles economically.

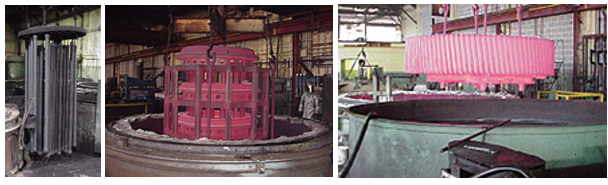

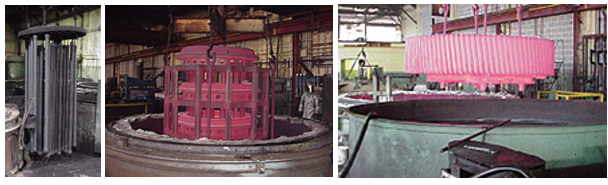

As part of its continuing maintenance improvement program, Metlab recently completed a rebuild and upgrade of its two large heat-treating furnaces. These furnaces designated P-1 and P-2 are believed to be the largest atmosphere-controlled pit furnaces in North America. With work zones measuring 12′ in diameter by 8′ tall and 15′ in diameter by 10′ tall, the equipment is used to neutral harden, carburize and harden, nitride, anneal, and stress relieve large components or multiple quantities of parts. With a capacity of up to 50,000 pounds per heat treat cycle, typical components processed include large gears and bearing races, rocket exhaust nozzles, forgings, castings, large weldments and other industrial components.

A load of windmill bearing races rasing from Metlab’s furnace designated P-1 before quenching in an 18,000-gallon oil tank. Each of the three races measures about 6 feet in diameter by 12 inches tall, weighing more than 2,000 pounds after carburizing.

Capital expenditure of more than $200,000 included new nickel base alloy retorts, cast ceramic floors, insulation, and upgrades to the furnace structure. The furnaces utilize different atmospheres to process parts including endothermic gas for neutral hardening and carburizing, ammonia for nitriding, or nitrogen and argon for scale-free processing. The furnaces rely on sand seals to contain the different gases. The sand seals for both furnaces were also redesigned and replaced. In addition, finned copper tube coils for cooling the sand seals were changed with closed welded stainless-steel chambers for better efficiency.

The rebuild to each furnace took about a month. While the nickel base alloy and stainless steel for the retort and sand seals were purchased as fabrications, Metlab maintenance personnel took over 350 hours to weld the different components together. A temperature uniformity survey (TUS) after completion demonstrated that the furnaces meet the strict requirements of AMS 2750E.

Metlab maintenance personnel welding the cooling chamber for the sand seal on the furnace.

As part of the upgrades, Metlab utilized funds received from a Small Business Advantage Grant from the PA Department of Environmental Protection.

This grant was used to incorporate a closed loop recirculating water system to cool the sand seals and fans of each furnace. The cooling water requirements of the furnaces are more than 20,000 gallons per week. The savings in water, not to mention the environmental benefits of recirculating water, are substantial and were recognized by the DEP as a significant benefit, resulting in the grant. Equally important is the elimination of the need to discharge heated water into the sanitary sewer system.

P-2, Metlab’s largest atmosphere-controlled furnace, showing the new nickel base alloy retort and sand seal installed. Also shown in the foreground is plumbing for the new water cooled sand seal.

Rocket exhaust nozzle forging is hardness inspected by a Metlab inspector, after normalizing, hardening and double tempering in Metlab’s largest furnace, P-2.

The Small Business Advantage Grant provided a 50% matching grant for funds spent on the equipment to Metlab. The cost of the recirculation system, purchased from Dry Coolers, Oxford, MI, including piping modifications and installation was about $35,000.

Metlab began the planning and purchasing of the furnace upgrades and cooling equipment in late 2016. Acquisition of funding, as well as material and components, allowed the project completion in early 2018.

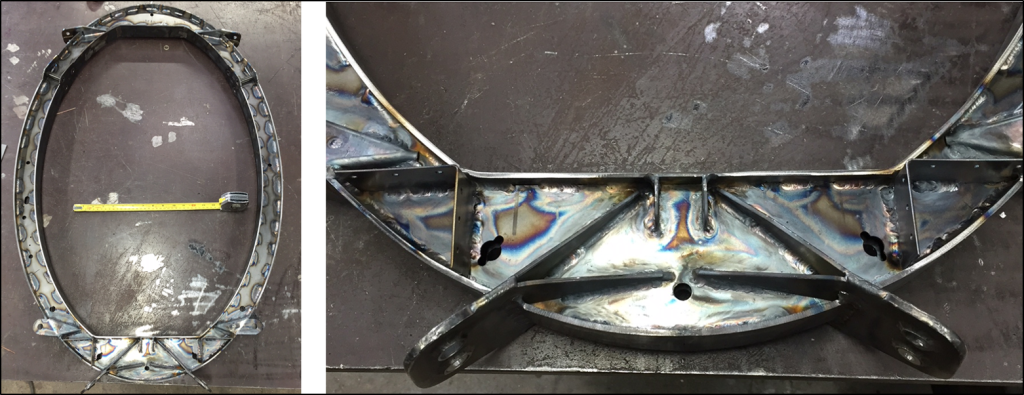

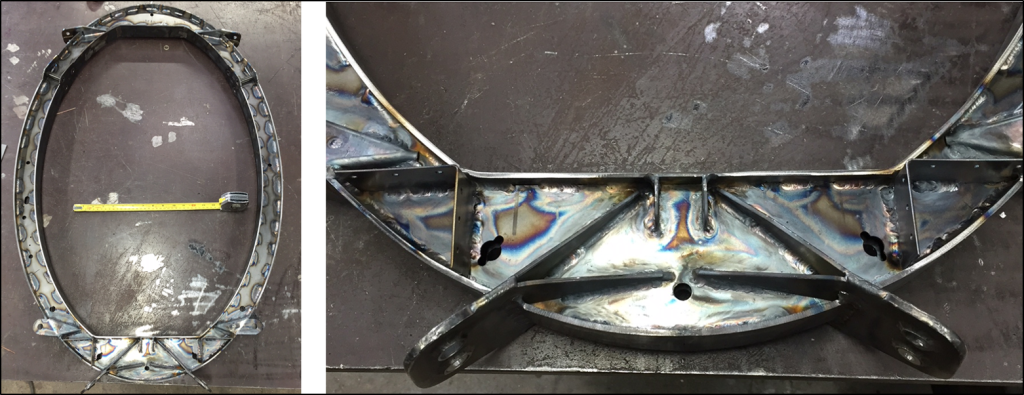

Metlab comes across many unique and interesting heat treating projects each year. Some have a history lesson to accompany the project. Recently, a newly fabricated structural bulkhead for a Ryan ST-A historic aircraft (circa.1934), was treated in the Metlab facility. The customer, Classic Metalcraft, was referred to Metlab by another heat treater that did not have the equipment to properly process the large part.

Ryan ST-A (Aerobatic) training aircraft circa. 1934

Ryan Aircraft was the manufacturer of the famous Spirit of St. Louis airplane. The Ryan ST’s were a series of two-seat, low-wing monoplane aircraft. They were used as sport aircraft, as well as trainers by flying schools and the military of several countries. The “ST” series (for “Sport Trainer”) was the first design from the company, introduced in 1933. This aircraft was followed by the “ST-A” (A for Aerobatic) which was developed with a more powerful engine.

“We manufacture aircraft parts for displays and museums,” states David Paqua from Classic Metalcraft. “We recently expanded our practice to accept complete restoration work for antique aircraft. Enter the Ryan STA. We decided to produce an exact replica of the Ryan. We obtained copies of the Ryan factory drawings and proceed to fabricate components for the fuselage, landing gear and wings. The most difficult part that needed to be fabricated was the #2 bulkhead. Not only is it tough to replicate without heavy pressing equipment, but it requires heat treating by a knowledgeable firm to prevent distortion. This is where Metlab came into the picture.”

The bulkhead component is a structural piece fabricated with 4130 steel. This segment was located just forward of the instrument cluster. The #2 bulkhead component carries all the stress of the flying wires, landing gear as well as the wing attachments. It was vital indeed to properly fabricate and heat treat this assembly while maintaining a flat section.

The fuselage jig is allowing accurate positioning of the bulkheads and upper and lower stringers. The bulkheads will be covered by a 2024 alloy aluminum skin of .032 thickness.

Paqua explains, “The skin of the aircraft is affixed to the bulkhead. It is critical for the part to have the proper minimum mechanical properties to support the skin as well as remain in shape through the heat-treating process to maintain the aerodynamic characteristics of the aircraft.”

Metlab developed a special fixture to maintain the flatness of the component during processing. Additionally, Metlab consulted with the customer and advised them to tack weld additional bracing inside the component to keep the integrity of the shape and help with the flatness of the entire component during the heat-treating process.

Bulkhead component prior to heat treating.

The physical dimension of the bulkhead is 26” wide X 39” tall and about 2” in section size. The part is quenched and tempered to 180,000 PSI UTS, minimum, about HRC 40 – 44. The part was processed in one of Metlab’s 4′ diameter by 16′ work zone pit furnaces and then clamped on a flat plate for tempering to maintain flatness. Post heat treatment inspection consisted of verification of the hardness and flatness.

Watch The Video:

|