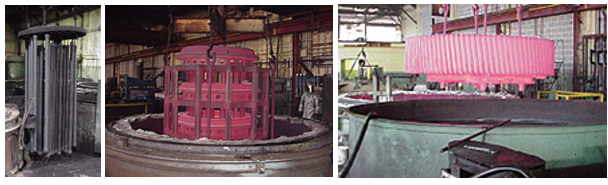

Metlab has a long history of supporting academia to encourage and educate young engineering students. This past October, students from the Industrial and Systems Engineering program at Temple University accompanied by their professor, Dr. Julie Drzymalski, toured the Metlab heat treating facility. The purpose of the tour was to expose the freshman and sophomore students to manufacturing and also stress the importance of heat treating to the success of engineered metal products. Each Metlab department was featured along the tour route, including vacuum heat treating, metal quenching, induction flame hardening, carburizing, nitriding, black oxide treatment, and several other process areas. The students also visited the quality control department, which is complete with a metallurgical lab.

Industrial and Systems Engineering Program at Temple University

students getting ready to tour Metlab’s Heat Treating Facility.

The students were guided by Mark Podob, Metlab’s Company President. “Providing a “hands-on” opportunity for engineering students gives them an invaluable experience to learn what it takes to bring products and parts to life.” Podob remarks. “We are committed to supporting students and faculty to keep young minds engaged with manufacturing processes, equipment, and employees. In fact, Metlab hires students from Temple and other universities for both internships and full-time employment.” Dr. Drzymalski noted that Metlab uses 5S Lean Manufacturing in its operation, which was just covered one of her recent classes with the students, emphasizing classroom education with real-world engineering.

Other processes featured during the tour included Annealing, Heat Treat Stress Relieving, Straightening, Carbonitriding, and Cryogenic Treatment.

For questions about Temple University’s Engineering Programs, Dr. Drzymaksi may be contacted at Julie.drzymalski@temple.edu.