Cryogenic processing is a special type of heat-treating process that involves cooling heat-treated steels and other metals to temperatures lower than -300°F. The deep chilling of heat-treated parts allows the metal molecules to be brought to “cryogenic stillness” to improve wear characteristics. When heat-treated steels are cooled to extremely cold temperatures, retained austenite is transformed to martensite, completing the heat treatment process. Retained austenite is brittle, and if not transformed to martensite, can cause chipping or cracking. As a worse case, retained austenite can act as nucleation sites for metal fatigue. Many heat treatment specifications, specifically for critical applications such as carburized gears or bearings, require deep-freezing the parts and a subsequent tempering operation to reduce or eliminate retained austenite and transform it to tempered martensite.

Cryogenic processing is performed by slowly cooling parts in a controlled bath of liquid nitrogen or a freezer, holding the parts until equilibrium is reached with the liquid’s temperature. Nitrogen is a liquid at -320℉. Cryogenically processed parts are generally held for one hour per inch of thickness. They are then gently heated to room temperature. For carburized and hardened steels and alloy steels, a final tempering at 300℉ for one hour per inch of thickness is done; tool and stainless steels are tempered at a higher temperature appropriate for developing required hardness and other properties. After the final temper, the microstructural changes are complete. The resulting part is significantly stronger and tougher than the unprocessed component.

Benefits of cryogenic processing include:

• Increased resistance to abrasive wear

• Improvement of the properties of the core of the part, not just the surface

• Decrease in residual stresses while increasing toughness and dimensional stability

• Parts may be subsequently reground or machined without affecting the results of the cryogenic process.

While the applications for cryogenics at times appear to be unlimited, parts that benefit from the process include:

• Knives including cutlery, hunting, diving, survival, and general blades; also, metal shear blades. Cryogenically processed knives made from tool and stainless steels like A-2, D-2, and 400 series stainless steel hold their sharp edge longer than their untreated counterparts.

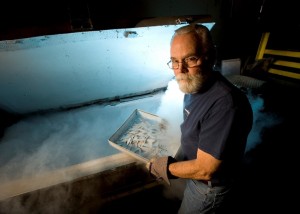

Operator removing a batch of cryogenically processed knife blades from a dry freezer prior to final tempering operation,

Blade Magazine, April 2012

• Forging dies – Cryogenic treatment of H-13 tool steel result in microstructural changes like fine martensitic structure, increase in carbide density, and uniform distribution, which improves hardness impact toughness, wear and stress rupture properties as compared to conventional hardened and tempered H-13 resulting in up to 25% longer tool life.

• Metal cutting tools like drills, taps, and dies, end mills, gear hobs, and broaches exhibit up to a five times improvement in tool life. Carbide tools also show enhanced performance believed to be from a shrink in the material filling in micro-voids between the tungsten carbide, titanium carbide, and/or tantalum carbide particles and cobalt binder. Medical and surgical tools and instruments also benefit from the process.

Courtesy, RE Music, September 2019

• Gears and bearings made from 8620, 9310, and 18CrNiMo6-7 are susceptible to premature failure if they are not cryogenically processed to convert retained austenite to tempered martensite.

• Automotive applications including brake rotors, transmissions, clutches, brake parts, rods, crankshafts, camshafts axles, bearings, ring and pinion, heads, valve trains, differentials, springs, nuts, bolts, washers are also beneficiaries of cryogenic processing. Enhanced performance makes cryogenics a staple of NASCAR, Formula 1, Drag Racing teams.

• Rock mining tools, specifically pistons, the key component in a hammer, are made from highly alloyed steels. Their repetitive impact against the drill bit in the tool makes them subject to high wear, chipping, and fatigue failures. Hammer pistons are carburized and hardened and then deep-frozen to improve tool life.

Hammers and drill bits for rock mining. The pistons located in the hammer are subject to repetitive impact against the bit, making them susceptible to failure by chipping or fatigue. Cryogenic processing of the pistons improves tool life.

Courtesy, NUMA Hammers and Bits.

It is important to note that cryogenics is not a substitute for heat treating but an enhancement. It adds a critical finishing touch to the heat-treating process. It has seen limited acceptance and use, mainly due to a lack of understanding of the technology. Except for the conversion of retained austenite to martensite, changes in other microstructural features are not visible with a standard laboratory metallograph. But changes in the lattice structure of the metals cannot be disputed; reduced residual stresses and the performance benefits of the process are well documented.

Metlab has extensive experience with cryogenic treatment for a wide variety of applications and can consult with you to provide the best solution to meet your product specifications.