Recently, Metlab was awarded a contract to heat treat camshafts. The manufacturer of the camshafts target market is NASCAR racing engines, as well as specialty aircraft, marine engine and industrial engines. They also make camshafts to order, and Metlab has in fact heat treated some cams for Model T Fords and other antique cars.

These camshafts are manufactured from 8620 or 9310 steel, range in size from 1 1/2″ – 3 1/2″ O.D. x 24″ to 72″ long. The heat treating is done with the parts in the vertical position, resulting in a product which is straight within 0.005″ T.I.R. Heat treatment requirements are a case depth of 0.120″ minimum, and surface hardness in excess of HRC 62. Cryogenic processing in-between tempering is required to minimize retained austenite and increase camshaft performance. Metlab heat treats the product in one of its two long pit furnaces, which can handle parts up to 16′ long. Metlab can comfortably heat treat up to 48 camshafts in a cycle. If straightening is necessary, this will be accomplished on one of two 100 ton presses located in-house. Normally the product turn-around is within a week or less.

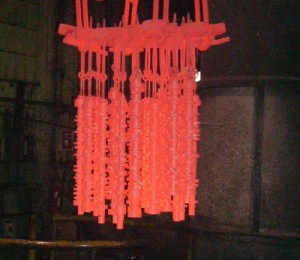

Load of camshafts being removed from Metlab pit furnace after carburizing, prior to oil quenching.

Some camshaft manufactures use induction hardening for hardening the lobes of camshafts – this is for high volume, relatively inexpensive production cams where the performance is not as critical is it is for racing engines. Some camshafts are also nitrided, but again, the case depth is shallower, and this would be for less critical applications.

Carburizing tends to be more expensive than the other two processes, but again, the longevity of the product is much longer. The heat treating process is critical to ensuring a high quality finished product as well as providing longevity to the high performance camshafts. Keeping the parts within case depth, hardness and straightness tolerances are key factors in overall quality control

Metlab was selected because of their commitment to quality, turnaround time, and with deep pit furnaces capability to do long slender parts and maintain straightness. We normally process about a dozen or so cams per heat treat cycle, have the capability to process up to about 36 per load, and have been doing about 50 a month. The parts are shipped to a domestic manufacturer of camshafts who distributes them globally.

Mark Podob

Vice President of Sales

Metlab Heat Treating