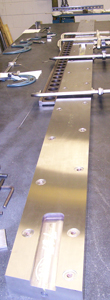

Metlab has shipped Machine Ways used to guide the track wheels of a precision industrial aluminum machine used for cutting wing segments and fuselage frames for commercial and military aircraft. Metlab chose A-2 tool steel as a replacement for the original cold fused flame hardened bi-metal steel design, which failed at the junction of the two dissimilar metals. The selection of through hardened A2 eliminates the need for complete replacement of the machine ways due to wear in service.

The Machine Way consists of eleven 12 foot long bars connected end to end, 2″ thick by 6″ wide, match ground to ± 0.003″ in length, ± 0.0005″ in thickness, with a maximum joint gap < 0.004″ between adjacent bars. The overall Machine Way is over 130′ long when installed.

Metlab was chosen to manage the entire project which involved partnering with the material supplier and grinding source to solve the unique problems presented by the Machine Way design. A2 tool steel needed to be obtained in the special length and size. Domestic material was purchased from the one source in Illinois which allowed for timely delivery.

The bars were heat treated vertically in Metlab’s unique 48″ diameter by 16′ long vertical pit furnaces under a protective atmosphere to ensure no decarburization or oxidation. The individual bars were straightened to less than 0.050″ in special fixturing provided by Metlab. Precision drilled and tapped locating holes (over 24 on the length of each bar) needed to be placed in the bars before heat treating. The use of low expansion A2 selected by Metlab allowed for predictable compensation for movement during heat treatment. The finished bars were then precision ground.

The bars were heat treated vertically in Metlab’s unique 48″ diameter by 16′ long vertical pit furnaces under a protective atmosphere to ensure no decarburization or oxidation. The individual bars were straightened to less than 0.050″ in special fixturing provided by Metlab. Precision drilled and tapped locating holes (over 24 on the length of each bar) needed to be placed in the bars before heat treating. The use of low expansion A2 selected by Metlab allowed for predictable compensation for movement during heat treatment. The finished bars were then precision ground.

Metlab’s expertise in overall project management, background in material selection, and experience with large shape heat treatment produced a dramatic improvement in the component without a sacrifice in the machine design.

Mark Podob

Vice President of Sales

Metlab Heat Treat